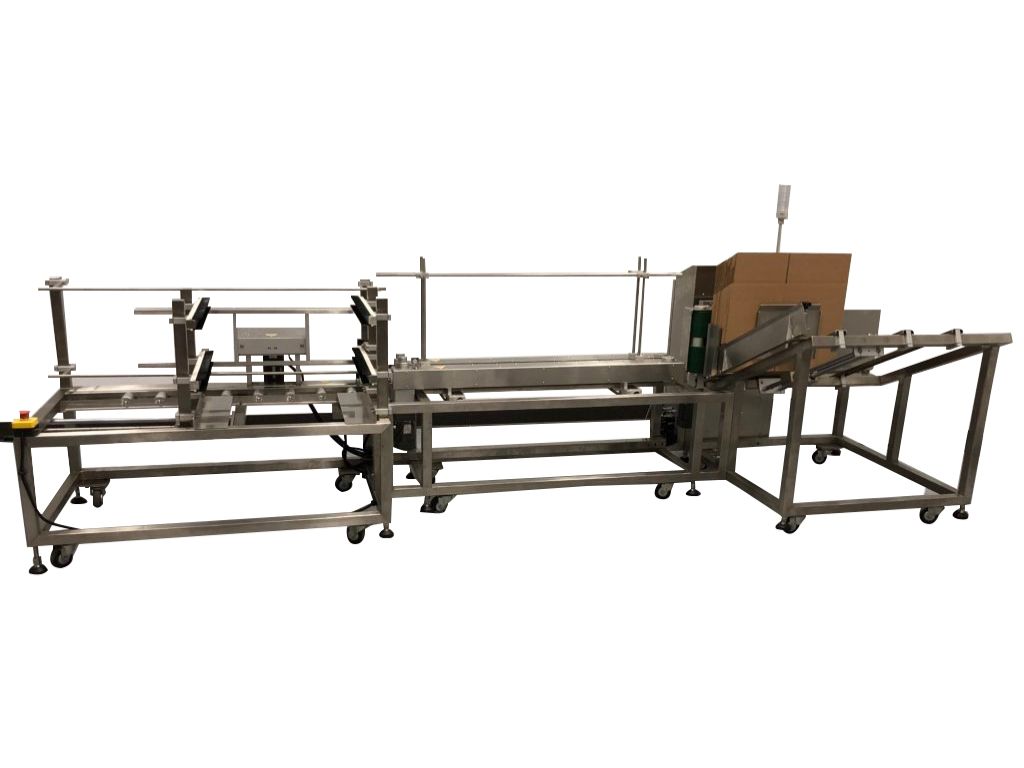

The VCT-3000 Vertical Case Transport is designed to run flat cases before they are erected and filled. The system can be integrated with ink jet printers or labelers for marking up to all four sides in a single pass. Speeds of up to 200 feet per minute get the job done fast. The system requires no plant air. The system comes with a belt feeding system on the in-feed, hugger belt system for the drive, and stepper driven re-stacker. Designed to run 24/7 with minimal maintenance. The system is built out of stainless steel and aluminum. The PLC allows for many features. All speeds are independently adjustable and saved by recipes.

VERTICAL CASE TRANSPORT: VCT-3000

VCT-3000 Vertical Case Transport with Ink Jet Printers or Labeling Systems

Print all four panels in one pass

• Speeds up to 196 FPM

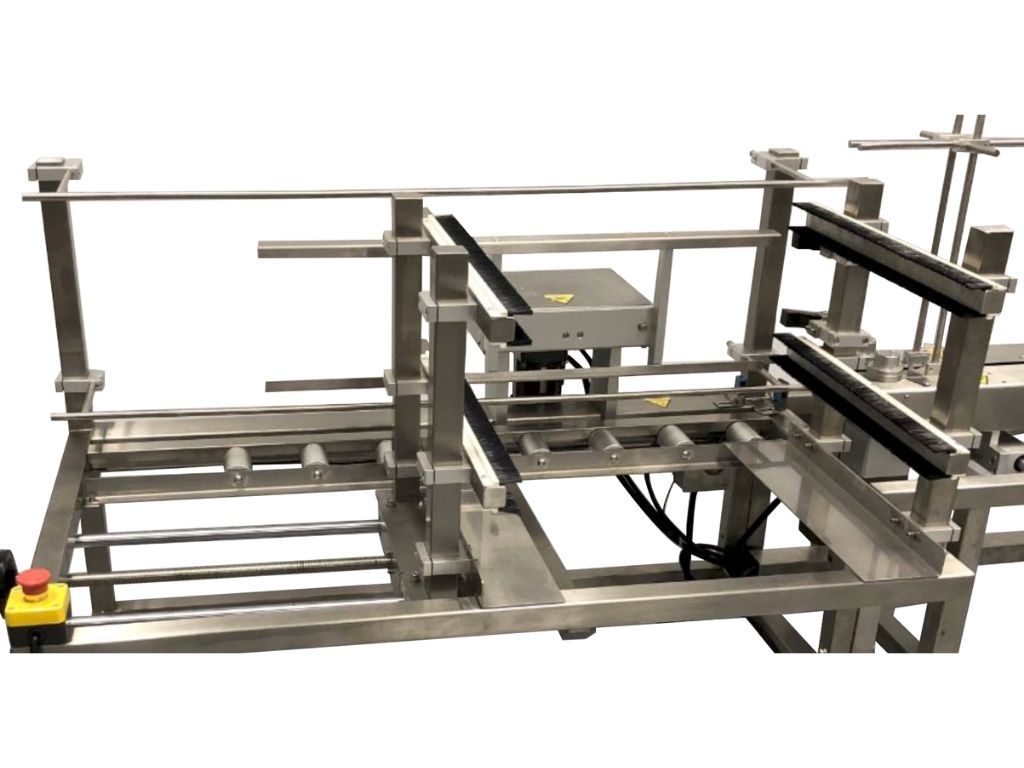

• Belt driven In-feed hopper

• Hugger belt drive system, spring loaded

• Re-stacker

• PLC controlled, Recipes for different product setup

• Integrated with Printers and Labelers

• Independent Variable speed adjustment

• NO PLANT AIR needed

Belt Drive in-feed hopper

• Holds 40 to 60 folded cases

• Folded length 18” to 39” (standard machine)

• Folded height 12” to 30″ (standard machine)

Controller

• PLC controlled, touch screen interface

• Stainless Steel Cabinet

• Voltage: 120 VAC, 20 amps, 60 Hz

• Alarm light output

• Emergency Stop

Hugger Drive Belt Section

• Independent speed control

• Spring loaded for various case thickness

• 48” overall length

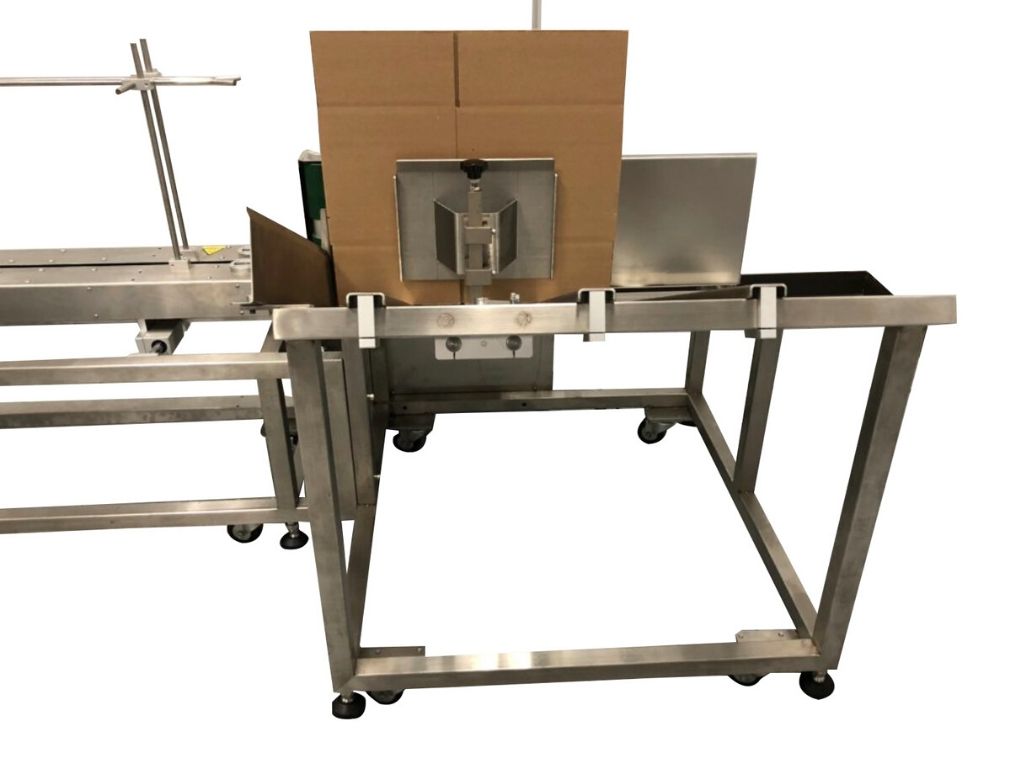

Stepper driven Re-Stacker

• NO PLANT AIR needed (standard machine)

• Restacks all cases

• Adjustable holding brushes

• Continuous operation – no need to

stop process for material loading and

unloading

• Optional reject for inspection systems