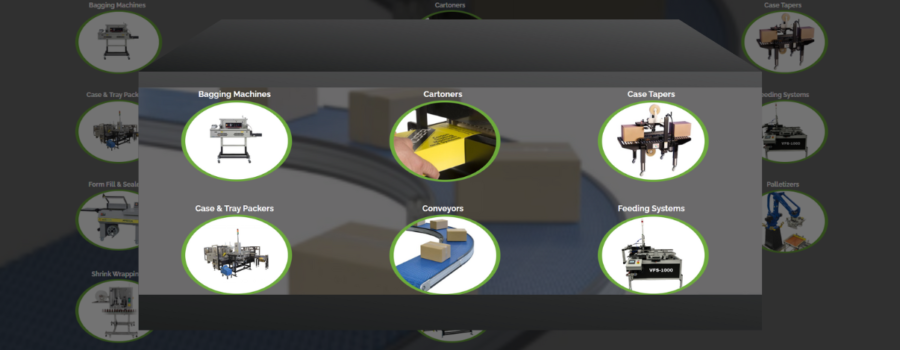

At Automating Cannabis Packaging Equipment, we understand that finding the right packaging machines for your cannabis products can be a daunting task. But don’t worry, we are here to assist you! We offer a wide range of top-of-the-line machinery models, such as bagging machines, cartoners, case tapers, case & tray packers, conveyors, feeding systems, form fill & sealers, and more! Our products are designed to help you efficiently label, mark, code, and package any cannabis product. Trust us for all your cannabis packaging needs, and you won’t have to waste any more time searching. And we have so many packaging equipment categories that we had to break our blog into two parts!

Bagging Machines:

Bag Closing & Sewing Machine

If you have a large format bag you need closed, we have the solution for you. Our bag closing and sewing systems have been an industry standard for more than 100 years. Featuring the most complete range of innovative bag sewing and sealing equipment:

Features:

- Hand-held portable sew systems

- High-speed bag sewing systems

- Hot air sealers

- Pinch bag

- Hot melt

- Pinch bag liner

- Poly-through-paper

- Wire tie

- Ring bag closures

Bag Sealing Equipment

Our industrial bag sealing equipment is known for their durability, compact design, and innovative features, and are easily integrated into semi or fully automated bagging lines.

Features:

- Pinch style bag closers

- Hot melt adhesive closers

- Hot air sealers

- Pinch inner liner sealers

- Full line of plastic bag sealers

Open Mouth Bagging

Our open-mouth bagging solutions continues to expand due to their rugged reliability and performance in the most demanding production environments where pre-made open mouth bags are desired.

Compatibility:

- Poly

- Poly-woven laminate

- Paper

- Paper/poly lined

- Pillow side gusset

- Pinch style

Cartoners:

Mini Monoseal

The Mini Monoseal is a simple and safe semi-automatic carton flap glue sealer that can be used to seal carton end flaps, hinge covers, side glue joints, gable tops and other carton styles.

Features:

- Portable, self contained table top design

- Simple and proven ECONOSEAL hot melt glue pot system

- Foot pedal cycle start

- Quickly adjustable for different sizes without the need for tooling

- 115 volt (optional 220 volt) No Air Required

Twinseal

The Twinseal is an economical carton sealer that glues two flaps simultaneously and can be adjusted to new sizes in just minutes.

Features:

- Sanitary construction (essentially stainless steel)

- Up to 30 cartons per minute (depending on carton style and other factors)

- Hand Crank Lateral Adjustment for fast, easy changeover

- Automatic Cycle

- Left-hand, Right hand or Straight back delivery chute discharge

- Accommodates glue sealing or hot air closure for paperboard or corrugated cartons

Case Tapers:

Our case tapers side belts are great for light or heavy weight, narrow or small boxes. It is ideal for void-fill cases where the packaged product does not support the box.

Features:

- Plug-in and go operation.

- Fast and easy box size changes

- Industrial strength side belts

- Interchangeable top and bottom tape cartridges

- Emergency stop button

- Adjustable leg extensions

- Casters for transportation within plant

- Front and rear pack tables to allow for case packing

- Top squeezers push top flaps together for accurate case sealing

- Powder coated 12 gauge steel

- Low maintenance, no air required

Case & Tray Packers:

Our case and tray packing equipment protects product presentation with advanced equipment for case packing, tray erecting and cartoning finished packages.

Features:

- Full line of standard and customized wraparound case

- Full line of intermittent and continuous motion systems

- Integrate case erecting

- Product Loading

- Container Sealing into a turnkey end-of-line packaging solution.

Conveyors:

Hugger Belt

Our hugger belt transfer conveyor is used as a bottomless conveyor integrated with an industrial inkjet coder to code bottles or other products. It is also often used as a bottle or product transfer conveyor.

Standard Functions:

- Bottom Code various types and sizes of products.

- Open design below belts for easy print head placement.

- Safe design with no sprockets or chain underneath belts.

- Ensures a smooth transfer of products from one conveyor to another.

- No more products falling over due to metal transfer plates.

- Easy and quick set up for various size and shaped of products with turn handle adjustments.

Turntable Conveyor

Our turntable conveyors are designed for accumulating and unscrambling products at various points during the conveying or cannabis packing processes.

Applications:

- Canisters

- PET Bottles

- Cups

- Glass Jars and Bottles

- Plastic Tubs

- Vials

Conveyors & Material Handling

As part of our automated packaging equipment solutions, we offer a wide variety of conveyors and material handling equipment to help deliver the options for our customers need.

Features:

- Metering the infeed of product into a form

- Fill & seal application

- Managing filled bags as they move through bag sealing

- Managing filled bags as they move through sewing

- Case Packing processes

Feeding Systems:

Vertical Feeder

The VFS-1000 system was designed for zippered pouch feeding and bag feeding that have long been an issue to run on traditional methods. The system allows for pouch labeling.

Features

- Up to 60 Pouches/Zippered bags per minute

- Adjustable in-feed conveyor, feeds on demand

- PLC controlled

- Recipes for different product setup

- Integrated with Printers and Labelers

- Alignment shuttle table

- Variable speed adjustment

Horizontal Feeder

The HFS-2000 system was designed for carton feeding, zippered pouch feeding and bag feeding that are difficult to feed with other traditional methods. Cartons, Pouches and Bags are laid flat, pick and placed onto a conveyor for Printing or Labeling.

Features:

• Up to 60 cartons per minute

• Adjustable in-feed hopper

• PLC controlled

• Recipes for different product setup

• Integrated with Printers and Labelers

• Catch bin or shingling conveyor

• Variable speed adjustment

Manual Feeder

The MFS-4000 Manual Feed System was designed to feed pouches and zippered bags laying flat to allow for downstream printing and labeling. Can be integrated with printers and labelers.

Designed to Feed:

- Zippered Pouches

- Zippered Bags

- Standup Pouches

- Autobottom Cartons

- Coffee Bags

- Foil Pouches

- Gusseted Bags

- Mylar Bags

- Paper Bags

Click here to read: Elite Packaging Machines for Cannabis Products Pt. 2

A.C.P.E. has the best equipment to automate any type of cannabis packaging facility, so contact us today and we can tell you more about our cannabis packaging equipment products and custom solutions that will fit your needs as well as your budget!