Did you know that the packaging processes of cannabis products represent one of the largest areas of financial risk within the industry? Understanding and managing these risks is a critical first step for any business aiming to mitigate the potential for financial losses. Risks in the cannabis sector can vary widely, encompassing catastrophic losses, business interruptions, issues related to physical security, cyber threats, and a perpetually changing regulatory landscape. Fortunately, one effective strategy for reducing the loss of cannabis products is the integration of advanced weighing and filling machines into the packaging processes. These automated cannabis packaging machines significantly streamline operations by reducing the need for manual filling tasks, which can consume hundreds, if not thousands, of labor hours. By automating this process, businesses can greatly minimize human error and ensure compliance with stringent regulations regarding precisely measuring controlled substances. Fortunately, you can reduce cannabis product loss with our Weighing & Filling Machine.

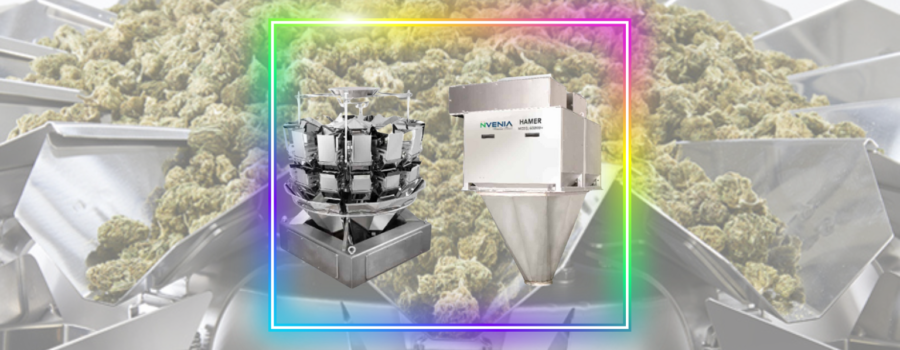

Our weighing and filling equipment stands out as one of the most accurate tools available in the market today. It is designed for high-accuracy applications where precision is paramount and operates at high speeds, making it ideal for various production environments. Additionally, our machines are user-friendly, facilitating easy operation, cleaning, and maintenance. A central feature of our offering is our comprehensive line of multi-head weighers. In essence, a multi-head weigher takes bulk cannabis products and efficiently weighs them into smaller, predefined increments based on parameters set in its software. The process begins when bulk product is funneled into the machine through the top infeed opening, which is typically supplied by an incline conveyor or bucket elevator.

Once the bulk product enters the machine, it is directed into a top cone and distributed into feed pans that gently vibrate, facilitating the movement of product from the center toward various buckets mounted around the periphery of the scale. The system is highly versatile, equipped with multiple options and software settings tailored specifically for the type of product being weighed and the target fill weight.

Each of the weight buckets is outfitted with an individual load cell that continuously monitors the weight of the product within it, even as additional product is fed into the bucket. To achieve the desired target weight, the scale’s sophisticated software calculates and selects a combination of buckets, summing their product load to precisely match the programmed weight.

This automation not only enhances accuracy and compliance but also increases efficiency in the packaging process.

WEIGHING & FILLING MACHINE IN ACTION!

Weighing & Filling Machine features next-generation technology for:

- Bagging scales and filling applications.

- Easily and efficiently manage the filling of free-flowing granular products like seed, feed, grains, dry sand, salt and more!

- Either semi-automatically or integrated into a full automated system.

Our cutting-edge packaging technology not only protects against financial and regulatory risks but also enhances operational efficiency, empowering cannabis businesses to excel in a challenging marketplace. Don’t wait—reach out to A.C.P.E. today for a personalized quote that will help your business reduce cannabis product loss with our weighing and filling machine!

A.C.P.E. has the best equipment to automate any type of cannabis packaging facility.

Contact us today and we can tell you more about our cannabis packaging equipment products and custom solutions that will fit your needs as well as your budget!