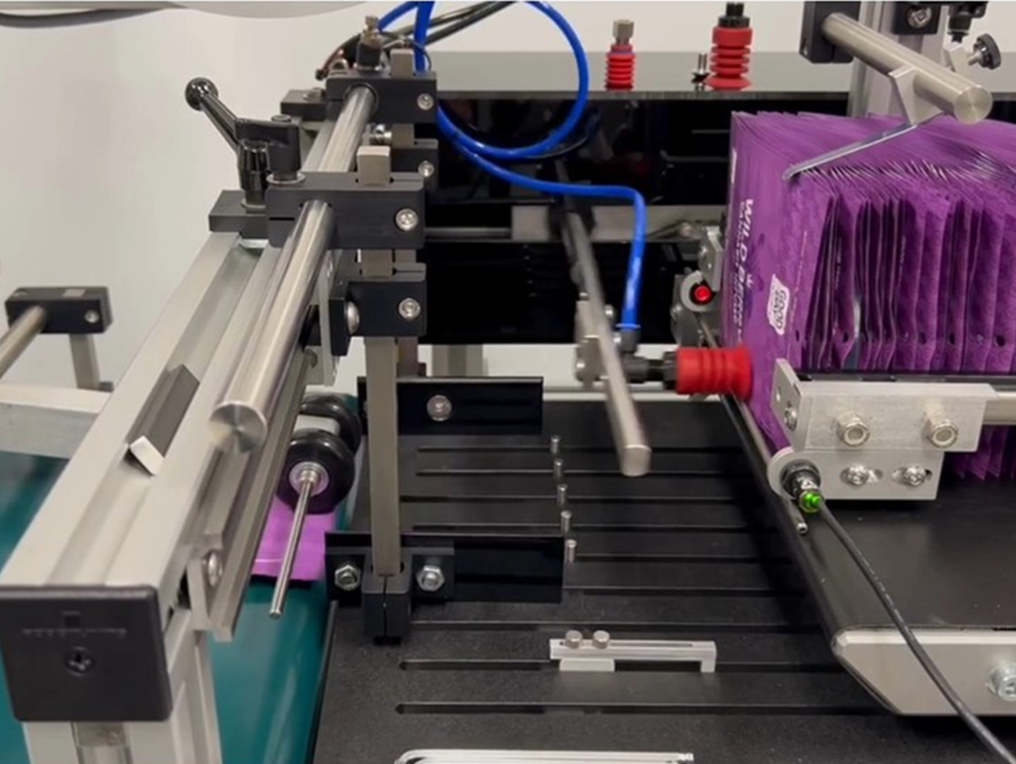

The VFS-1000 system was designed for zippered pouch feeding and bag feeding that have long been an issue to run on traditional methods. The system allows for pouch labeling. Stand-up pouches and bags are stood on edge, pick and placed onto a shuttle table, then pushed on to the downstream conveyor for printing or pouch labeling. The System can run up to 60 pouches or bags per minute depending on size of pouches and bags. Pouches and bags are aligned as they are pushed onto the receiving conveyor.

VERTICAL FEEDING SYSTEM: VFS-1000

Built to Feed Zippered Pouches for Downstream Printing & Labeling

- Up to 60 Pouches/Zippered bags per minute

- Adjustable in-feed conveyor, feeds on demand

- PLC controlled

- Recipes for different product setup

- Integrated with Printers and Labelers

- Alignment shuttle table

- Variable speed adjustment

Designed to Feed:

- Zippered bags

- Pouches

- Standup Pouches

- Foil Pouches,

- Auto bottom

- Cartons,

- Coffee Bags

- Paper Bags

- Gusseted Bags

- Mylar Bags

- And more!

In-Feed Conveyor

• Holds up to 30” of product

• Adjustable guides

• Product from 3” wide x 3” long up to 9” wide x 13” long

• Dual adjustable suction cups for

Controller

• PLC controlled, touch screen interface

• Painted Steel Cabinet

• Voltage: 120 VAC, 4 amps, 60 Hz

• Alarm output connections (2 Amp rating)

• Emergency Stop

Shuttle Table

• Aligns while pushing onto downstream conveyor

• Pins are removable

• 2” stroke

Digital Vacuum Sensor

• Detects when bag is on the suction cups