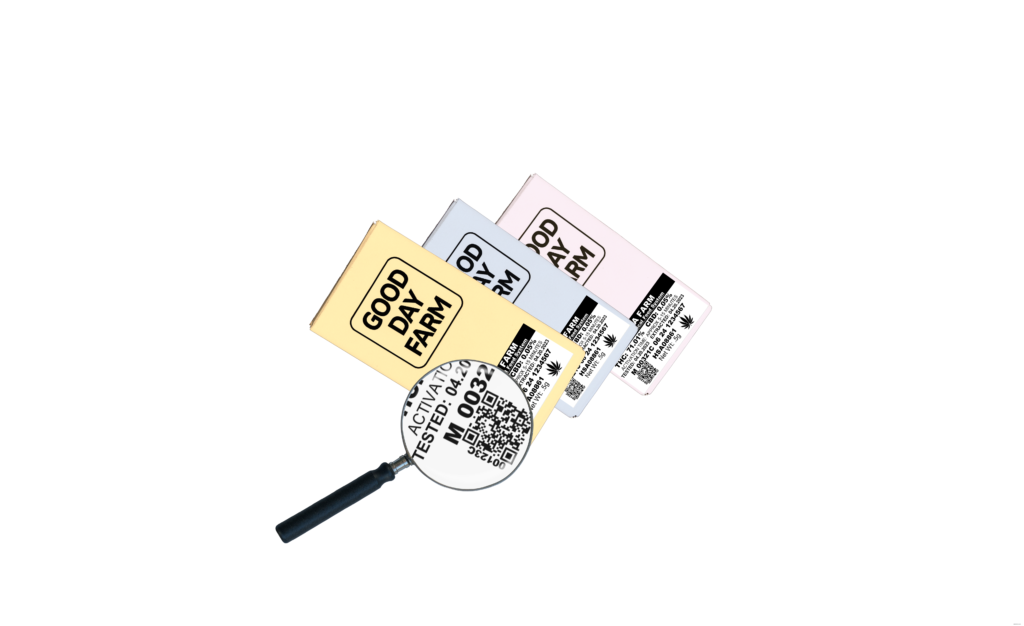

The HFS-2000 system was designed for carton feeding, zippered pouch feeding and bag feeding that are difficult to feed with other traditional methods. Cartons, Pouches and Bags are laid flat, pick and placed onto a conveyor for Printing or Labeling. The System can run up to 60 pouches or bags per minute depending on size of pouches and bags.

HORIZONTAL FEEDING SYSTEM: HFS-2000

Engineered for High-Quality Carton & Bag Feeding

• Up to 60 cartons per minute

• Adjustable in-feed hopper

• PLC controlled

• Recipes for different product setup

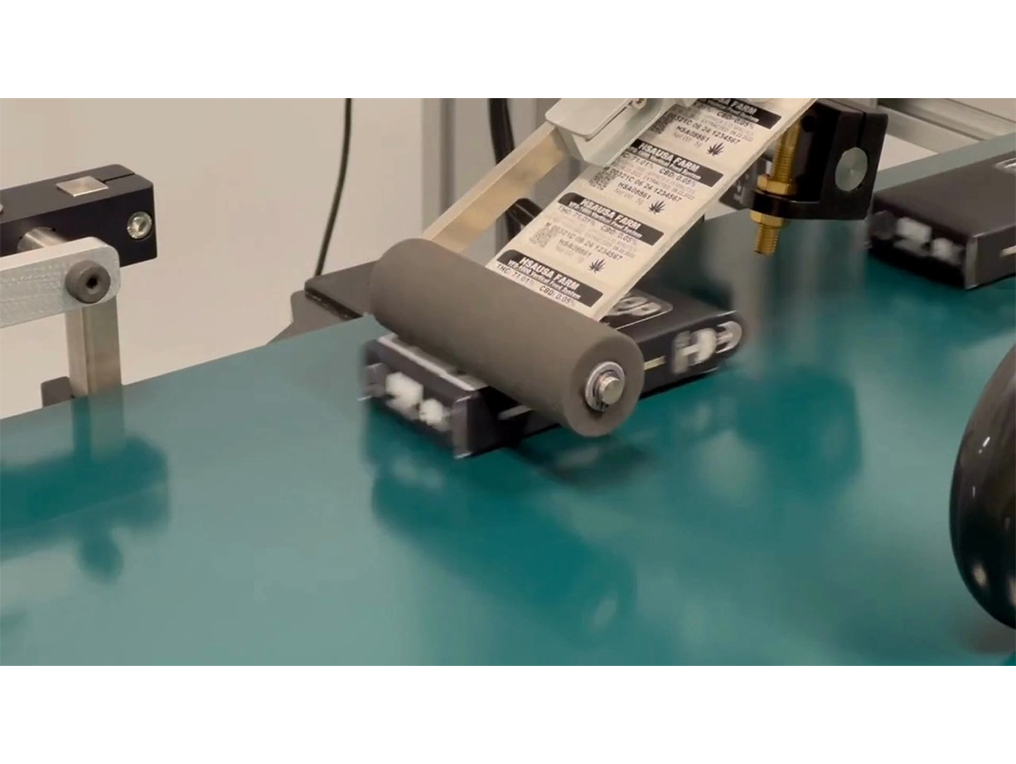

• Integrated with Printers and Labelers

• Catch bin or shingling conveyor

• Variable speed adjustment

In-Feed Hopper

• Holds up to 6” of product

• Adjustable guides

• Product up to 15” wide x 15” long

• Dual adjustable suction cups for proper picking

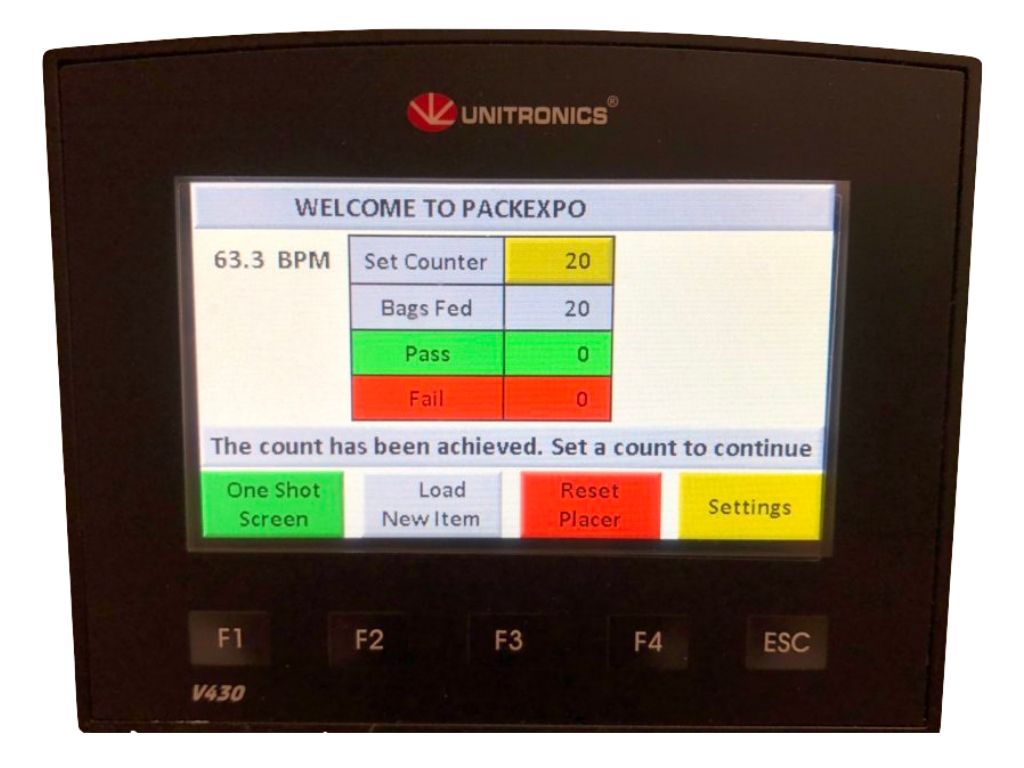

Controller

• PLC controlled, touch screen interface

• Painted Steel Cabinet

• Voltage: 120 VAC, 4 amps, 60 Hz

• Alarm output connections (2 Amp rating)

• Emergency Stop

Catch Bin

• Adjustable guides to handle product 15” wide x 15” long

• Wheel drives product out into the hopper.

Digital Vacuum Sensor

• Detects when bag is on the suction cups, attempts to pick again if bag is dropped.